Subsea Energy Solutions, based in the North East of England, service the global industries of Oil & Gas, Offshore Wind, Wave, Tidal & River Energy while also servicing the UK Ministry of Defence (MOD). They are an FPAL registered and ISO 9001:2015 certified company and work to the requirements of ISO 14001 & ISO 18001. They have a skilled team committed to high quality products and services. They provide project management, innovative design, in-house manufacturing, equipment assembly, load & pressure testing and onshore / offshore commissioning.

SUBFLEX™ Dynamic Vertebrae Bend Restrictor - The Innovative Solution to FPSO Risk Exposure

Subsea Energy Solutions have developed and patented a Dynamic Vertebrae Bend Restrictor system known as SUBFLEX™ for installation underneath FPSO hulls. They sought industry advice during the development of the product and took into consideration various parameters such as purchase cost, rapid offshore assembly, rapid installation, elimination of maintenance requirements and standardisation of components, to name a few.

SUBFLEX™ provides significantly increased levels of bending, shear and fatigue protection to tied-in and connected-up, cables, umbilical’s and risers, against highly dynamic sea-state environments underneath FPSO hulls. It increases the design life of cables, umbilicals and risers, saving significant time, cost and resources, procuring and installing replacement subsea assets.

Contrary to the function of Static Vertebrae Bend Restrictors, SUBFLEX™ requires an applied load or force to achieve product deflection. It provides stiffness, stiction and resistance against applied loads and forces, providing enhanced protection to the FPSO’s subsea assets. The systems load and force resistance value can be easily adjusted. Clients can select identical (homogeneous) elements or similar (nonhomogeneous) elements throughout the assembly, therefore designing the product to specifically suit the dynamic sea state condition underneath any specific FPSO hull.

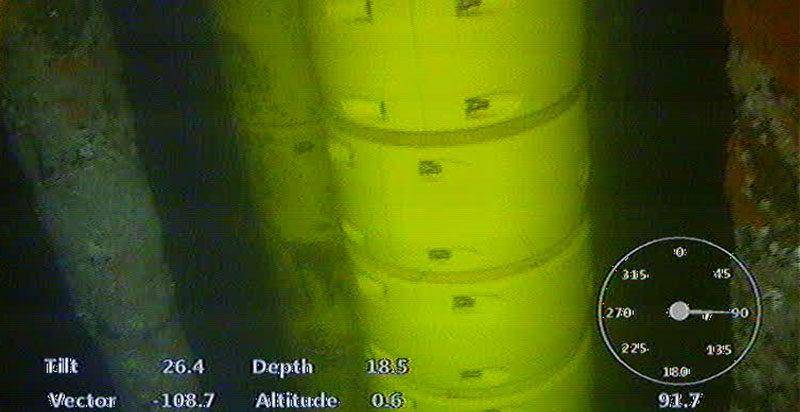

SUBFLEX™ offers standard assembly length of approx. 6 metres, bending moments in excess of > 500 kNm (50 Te / mtr) and shear capacity in excess of > 500 kN (50 Te). Three systems have been supplied to an International Oil Company and successfully installed underneath the clients FPSO.

Subsea Energy Solutions’ SUBFLEX™ product is the future of cable, umbilical and risers protection in free-span and dynamic environments and can significantly contribute towards the cost reduction of FPSO operation and maintenance. The system can be either retrofitted to existing subsea assets or installed during construction of new FPSO’s.

FPSO’s are a high cost high insurance claim environment and the quantity and nature of claims are well documented by FPSO owners and operators relating to the repair and replacement of cables, umbilical and risers. Past projects have encountered costly issues due to the difference between theoretical analysis and practical performance, leading to fatigue, failure, production slowdown and ultimately shutdown.

With current crude oil prices, there has never been a more important time for the FPSO community to come together and lend support to a fully coordinated, fully standardised approach for FPSO topside, waterline and subsea production protection solutions. SUBFLEX™ guarantee’s a reduction of FPSO insurance claims and a reduction of FPSO operation & maintenance costs.